The performance of JUTAIPEEK

®WR01 series products is as follows:

|

Performance

|

Test Method

|

Unit

|

Standard

|

|

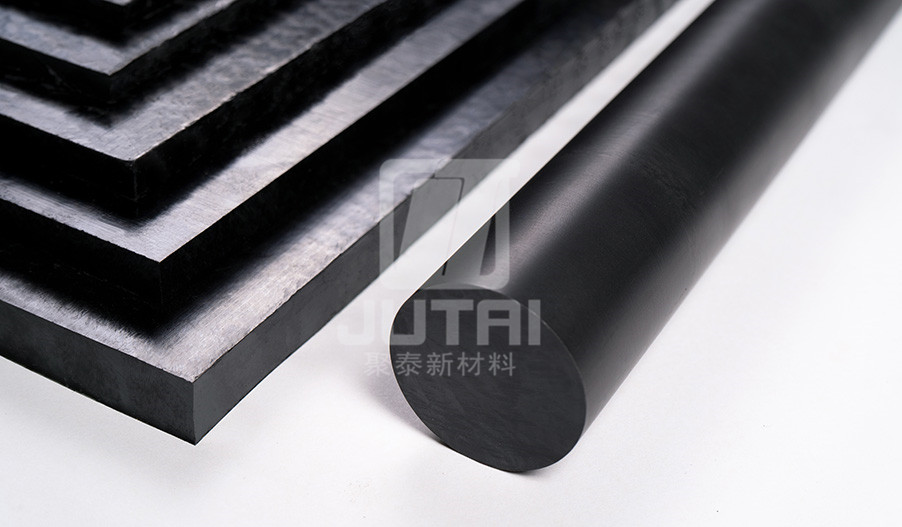

Color

|

Eye

|

/

|

black

|

|

Density

|

ISO 1183-1

|

g/cm³

|

1.43

|

|

Tensile Strength

|

ISO 527-2

|

MPa

|

≥75

|

|

Tensile Modulus

|

ISO 527-2

|

GPa

|

≥4.5

|

|

Elongation At Break

|

ISO 527-2

|

%

|

≥3

|

|

Charpy Impact Strength

|

ISO 179

|

KJ/m²

|

≥5.0

|

|

Flexural Strength

|

ISO 178

|

MPa

|

≥140

|

|

Flexural Modulus

|

ISO 178

|

GPa

|

≥5

|

|

Rockwell Hardness

|

ISO 2039-2

|

HRM

|

≥100

|

|

Melt Temperature

|

ISO 11357-3

|

℃

|

≥334

|

|

Thermal Conductivity

|

ISO 8302

|

W/(m•K)

|

≤0.5

|

|

Coefficient of Linear Thermal Expansion 20-100℃

|

ISO 11359-2

|

10-6/K

|

≤50

|

|

Long Service Temperature

|

UL 746B

|

℃

|

240

|

|

Heat Deflection Temperature

|

ISO 75-2

|

℃

|

≥260

|

|

Water Absorption (24h)

|

ISO 62

|

%

|

≤0.11

|

|

Flame Retardancy

|

UL 94

|

/

|

V-0

|

|

Frictional Coefficient

|

ASTM D3702

|

/

|

0.33

|

|

Wear Rate

|

mg/h

|

1.14

|

Notes: Frictional coefficient and wear rate were tested according to ASTM D3702, that is using thrust washer

testing machine. Rubbing pair is PEEK sample thrust washer and 45# steel washer, and the contact area is

1.29cm2, and the inner diameter of the PEEK sample is 25mm. The applied load is 0.35MPa and the rubbing

velocity is 2m/s.